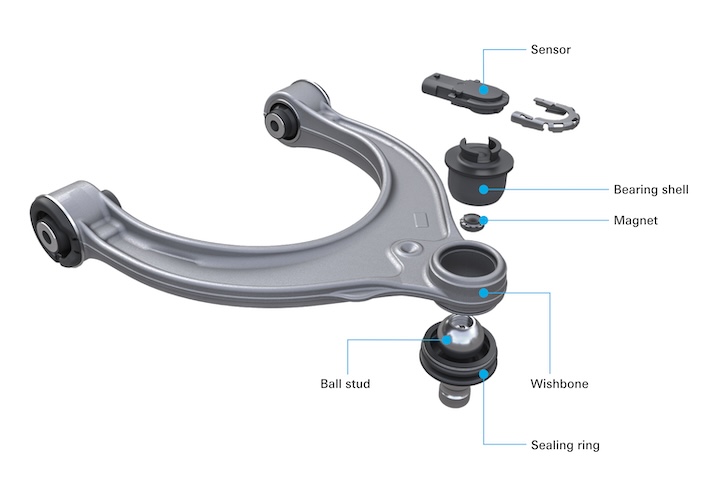

Cadillac has opted to equip its new all-electric Celestiq luxury sedan with ZF’s Smart Chassis Sensor, a high-tech system for determining vehicle ride height. The sensor system, developed in-house by ZF, is permanently integrated into each ball joint of the four-wheel suspension, with smart algorithms generating information for factors such as the electronic control of damping and headlamp levelling.

The location on the ball joints is important because the angle of the ball pivot integrated in the wheel joint changes during driving due to the compression and rebound movement of the wheel. The ZF system can reliably measure these specific changes in the angle, and it can interface with electronic systems from ZF or other suppliers.

In the Cadillac Celestiq application, the Smart Chassis Sensor system is permanently integrated into the ball joints, with two sensors in the front wishbones and two in the rear wishbones. This integration means there is no need for separate installation, which saves weight and cost, makes it less susceptible to weather conditions, and aids the reliability of signal quality.

“The series premiere of our Smart Chassis Sensor illustrates the importance of intelligent and robust sensors for new electronic vehicle features,” stated Steffen Reichelt, head of the chassis components product line at ZF. “With the help of evaluation algorithms, our sensor not only replaces conventional height sensors, it also significantly outperforms them in terms of the quantity and reliability of the data collected.”

Potential for more functions and new business models

The Smart Chassis Sensor opens up a range of applications for Cadillac. The initial usage for the data from the system in the Celestiq is for control of the damping and air suspension, and adjustment of the headlight range.

Depending on the degree to which the system is deployed and the number of vehicles that are networked, ‘road condition monitoring’ can also be implemented. In this use, the sensor detects irregularities in the road surface – such as potholes and road bumps – and adjusts the chassis to the conditions, adapting the vehicle damping to the road conditions and protecting important and safety-relevant chassis components from damage.

“The data collected by the sensor allows additional conclusions to be drawn about the vehicle, its surroundings and the road surface. These findings are particularly attractive for commercial vehicle users and fleet owners, but also for the maintenance of road infrastructure,” says Reichelt.

The data can also be used to feed driving dynamics applications such as ERC (Electronic Roll Control) roll stabilisation, and active or semi-active damping systems. Other systems can also be operated in combination to increase vehicle safety and comfort.