Automotive technology company, Continental has developed new vibration control technologies intended for engine mounting systems in electric vehicles (EVs), with China identified as a key market. The electric drive requires a special mounting component to isolate the high-frequency excitations of the engine, so Continental has developed concepts with a geometric design and special elastomer compound that allow the mounts to be optimally adjusted to the requirements of EVs.

Andreas Firla, who is responsible for product development of engine mounts in vibration control department at Continental Germany, explains, “Electric vehicles may be quieter, but their drives create excitations in the high-frequency range, which is more unpleasant for humans. The combustion engine makes a humming sound, whereas the electric motor makes a whistling sound. Furthermore, previously unheard noises such as rolling, wind and air conditioning come to the fore as they are no longer masked by the sound of the combustion engine.”

“With the aid of simulation tools, the properties of the mounts can be optimized in the early development phase. In order to validate these, we characterize the dynamic behavior of the components in the high-frequency range.”

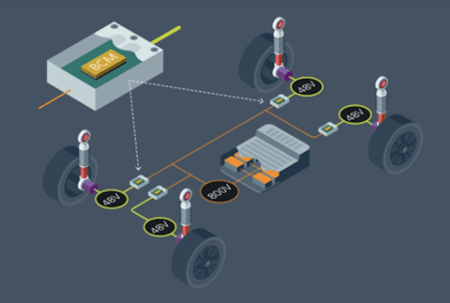

Continental’s engine and chassis mounts for electric motors are integrated in lightweight structural components made from aluminum or fiber-reinforced, high-performance polyamides, and depending on the material chosen, each sub-component is then designed and produced using a complementary material tailored to reduce disruptive noises and vibrations and insulate the driver from excitations.

Yimin Zhu, responsible for vibration-control-related R&D at Continental in China, explained the focus on this market: “China is already seen as the empire of e-cars and is leading the development of electric mobility. So far, development of the powertrain and a longer range are the priorities for all OEMs. Meanwhile, passenger comfort and wellbeing is playing an increasingly important role in the construction of electric vehicles in China.”

Continental is already working with leading Chinese manufacturers such as CHJ Automotive and NIO to further develop the designs. Continental’s high-frequency vibration test bench in Hanover, Germany, is also being used to test anti-vibration components and prototypes developed for Chinese manufacturers, up to a frequency of 3,000Hz.

Yimin Zhu added, “Our aim is to concentrate our expertise close to our customers. We are investing heavily in research and development and are working closely with our colleagues in Germany and at other sites to fulfil customer needs here in China.”