Continental is celebrating passing a landmark one million tests using its fully automated tyre braking test facility, located at the Contidrom test site near Hanover, Germany, since it was installed in 2012. Continental says the facility, known as the AIBA (Automated Indoor Braking Analyzer), is unique in the automotive industry, enabling precisely reproducible test processes to check the performance of new car and van tyres on different road surfaces, whether dry or wet, under laboratory conditions.

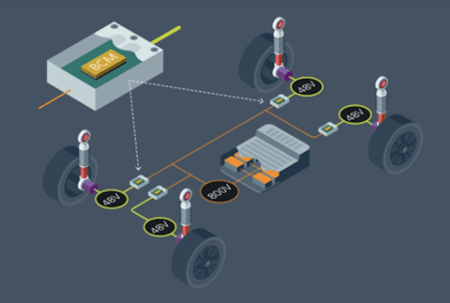

The stars of the facility are the Analytical Vehicle AIBAs (AVAs), which are automated rail-guided vehicles developed in-house that can be used instead of a car or van. The AVAs are automatically accelerated to speeds of up to 120km/h (75mph) along a track measuring almost 100m long. The vehicles are then braked autonomously on a 75m-long braking track. The acceleration force is provided by an electromagnetic linear drive derived from modern roller-coaster technology, powered by renewable energy.

“The AIBA facility is one of the most modern braking test facilities for tyres in the world. Even after being in use for more than 10 years. We can achieve a particularly high level of comparability of the test results in a fully air-conditioned, weather-independent, and fully automated environment,” stated Meletis Xigakis, head of global tyre testing at Continental. “Braking is essential for road safety. That’s why we put a lot of effort into being able to analyse the performance of our tyres as precisely as possible.”

More than one million test drives

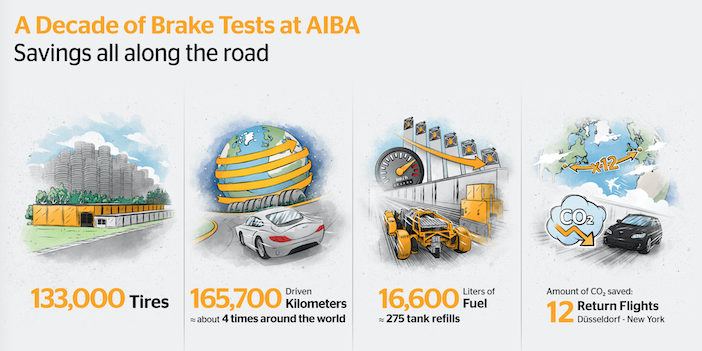

Since its commissioning in 2012, developers have tested more than 130,000 tyres using the AIBA, equating to more than a million ‘test drives’. Around two-thirds of all tyre braking tests at Continental take place in the AIBA facility, with a focus on prototype designs, for which the interaction of new or modified rubber compounds and tread designs is validated and optimised. The facility is also used to verify the performance of new serial tyres, enabling precise and vehicle-independent determination of the friction properties of tyres during braking manoeuvres.

The AIBA has delivered big benefits for workforce time and safety, as well as the environment, over the past 12 years. Continental estimates that the facility has enabled around 166,000km of intensive acceleration and braking tests to be carried out in the lab rather than on the track, saving 16,600 litres of fuel and almost 40 tons of CO2.

Tyre development is not only conducted at the AIBA though. Before a new Continental tyre model enters production, prototype versions will cover around 25 million kilometres on roller drum test rigs and test tracks – around 625 orbits of the earth – for evaluation purposes. This also includes test drives at Continental’s worldwide test tracks, with skilled drivers determining the subjective road performance of tyres.