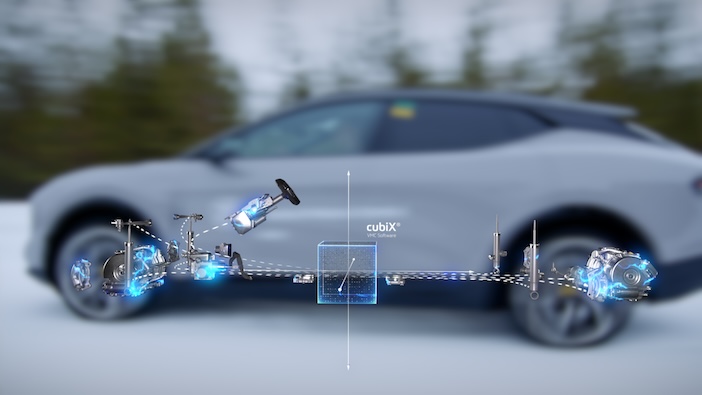

Optimising the dynamics of a vehicle chassis involves the precise coordination of multiple actuators, such as brakes, steering, damping systems and drive, to ensure that a car accelerates safely, brakes reliably and remains stable through corners.

ZF has worked to enable such coordination to be conducted using its CubiX software, and has now expanded the capability of the package to support the complex calibration of individual actuators during the vehicle development process. A new tool in the software, named CubiX Tuner, is designed to automatically calculate the interdependencies between actuators.

For example, says ZF, an electronic control unit (ECU) can now be configured with the manufacturer’s unique ‘brand DNA’ in just a few clicks, saving time, costs and effort when developing new vehicle models.

“Ensuring that a car behaves as requested by the OEM in all situations depends on several thousand parameters,” explained Philippe Gasnier, head of research and development of the ZF Chassis Solutions Division. After all, there is hardly a driving situation where multiple actuators are not working together.”

Thus, a chassis must be calibrated, including every single actuator in every possible position that is used for control interventions, before a vehicle can be put on the road. In this interplay, all influencing forces and variables must be considered, tested and verified.

“This is, to put it mildly, extremely complex,” added Gasnier.

However, the CubiX Tuner leverages the advantages of the software-defined vehicle to simplify and accelerate this process, which saves costs, effort and development cycle time – especially for platforms delivered with multiple drive configurations such as front-, rear- or all-wheel drive.

“While the algorithms handle the identification of core parameters, engineers can fine-tune the vehicle’s dynamics with precision, allowing application maturity to be reached much earlier,” said Gasnier.

Brand DNA at the click of a button

“For a long time, a car’s character was defined primarily by its engine,” stated André Engelke, head of vehicle motion control systems at ZF. “That’s changing in the age of electrification. Where once a combustion engine rumbled under the hood, an electric motor now often hums quietly. In other words, bringing brand DNA to life is increasingly becoming the responsibility of the chassis.”

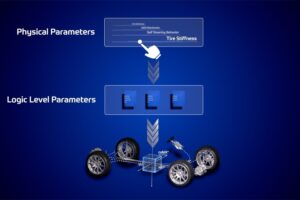

“Our customers can adjust chassis parameters at the vehicle dynamics level without having to dive all the way down to the algorithmic level,” added Engelke, adding that data and AI-driven methods can automatically adapt the complex interdependencies of dynamic functions during calibration.

“Put simply, if our customers notice during a test drive that the maximum steering angle during cornering needs adjusting, they can do it with just a few clicks. The cubiX Tuner then automatically calculates which additional parameters it needs to adjust and how,” Engelke added. This is done through an intuitive interface that automatically generates a ‘tuning map’ for the vehicle based on the OEM’s inputs and writes it directly to the ECU. The tool can calibrate not only ZF actuators, but also components from other manufacturers. An ‘Expert Mode’ makes it possible to dive even deeper into fine-tuning the chassis setup.

Test in virtual simulation

The CubiX Tuner will be available in two versions. One is a full version controlled via PC, and the other is a ‘Lite’ version that allows parameter adjustments to be made directly in the vehicle using a mobile app. The latter is compatible with both Apple CarPlay and AndroidAuto. Both versions have cloud connectivity for data backup and an AI-based optimisation feature that runs offline and locally.

The CubiX Tuner also allows OEMs to first test their calibrations in a virtual simulation before the parameters are written to the ECU and applied to the chassis. “This greatly simplifies before-and-after comparisons, as the car no longer needs to be tested on the track for every single parameter change,” added Engelke.