Mazda has developed what it believes to be the world’s first cold-stamped vehicle body parts made from 1,310 MPa-class high-strength steel, an achievement that can result in lighter weight vehicle bodies, which in turn can contribute to improved vehicle handling, stability and fuel economy. This work does not just represent a research project: Mazda has stated that such parts will be used in its new-generation Skyactiv-Vehicle Architecture, which will underpin upcoming models, starting with the all-new Mazda3.

Until now, cold-stamping of vehicle body structural members has only been possible with 1,180 MPa or lower-classed steel, due to the material’s formability and the difficulty of ensuring dimensional accuracy after processing. By working in collaboration with Nippon Steel & Sumitomo Metal Corporation and JFE Steel Corporation, however, Mazda claims to have found an appropriate set of processing conditions that make the process possible with the thinner 1,310 MPa-class high-strength sheet steel, while retaining the necessary yield strength – and crash safety performance.

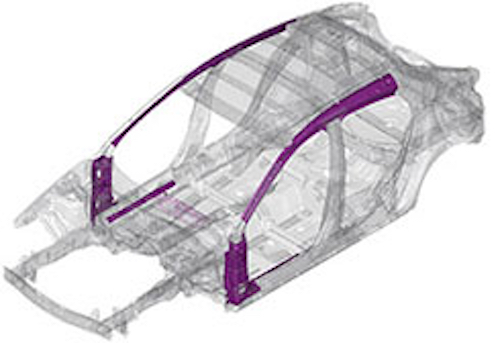

The forthcoming generation of Mazda3 will feature 1,310 MPa-class high-strength steel in the front pillar inner, the roof rail inner, the hinge pillar reinforcement, the roof rail reinforcement, the No. 2 crossmember and the side sill inner reinforcement, saving a claimed 3kg over the same parts in the previous model.