Monroe has introduced an all-new range of air springs for commercial vehicles that is available for and designed to be compatible with a wide range of trucks, buses and other applications from Mercedes-Benz, Iveco, DAF, Renault Trucks, MAN, Volvo, and other vehicle manufacturers.

The new range, under the name of Monroe Magnum air springs, has been developed using the company’s experience as an OE supplier to commercial vehicle manufacturers. Monroe’s engineers say they have identified and validated several unique spring design and construction improvements that can help maximise on-the-job performance and durability. These improvements include:

- Premium bellows manufactured from a formula of high-quality rubber materials to maintain flexible performance over a longer operating life while resisting ozone, dirt, road grime and harsh weather conditions.

- A flexible premium bumper design tested to withstand up to 89 kilonewtons (kN) of force without cracking or breakage.

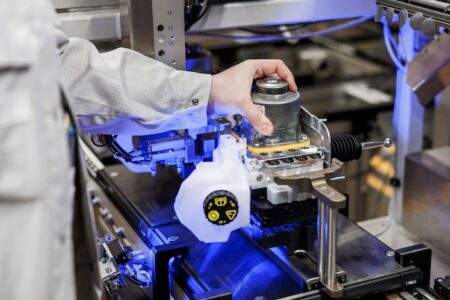

- Ultra-high-strength steel pistons engineered for extreme-load vehicles, or next-generation lightweight plastic pistons with an advanced anti-corrosion coating.

“Commercial vehicle air springs operate in a brutal environment that demands application-specific design enhancements, premium materials and high manufacturing standards. Monroe Magnum Air Springs are engineered and built for long-lasting performance and help keep vehicles safe in challenging conditions,” said Sylvain Gary, senior product manager, EMEA, DRiV.

The new Monroe Magnum range includes:

- Convoluted air springs, suitable for axle lifting in multi-axle vehicles, as well as pneumatic lifting and vibration isolation in industrial settings.

- Rollover air springs, providing enhanced lateral stability to help maintain vehicle control during cornering and with uneven loads.

- Complete assembly air springs, available both in durable lightweight designs (plastic pistons) and ultra-high-strength designs (steel pistons). Each air spring is engineered to maintain the corresponding vehicles’ correct ride height and centre of gravity, helping ensure loads remain stable and drivers safe in challenging routes.

“Air spring failure is a leading cause of vehicle downtime for fleets and other commercial vehicle operators,” added Sylvain Gary. “Distributors and service providers can help customers eliminate premature failures and other costly issues by offering air springs that have been engineered for reliability and durability.”