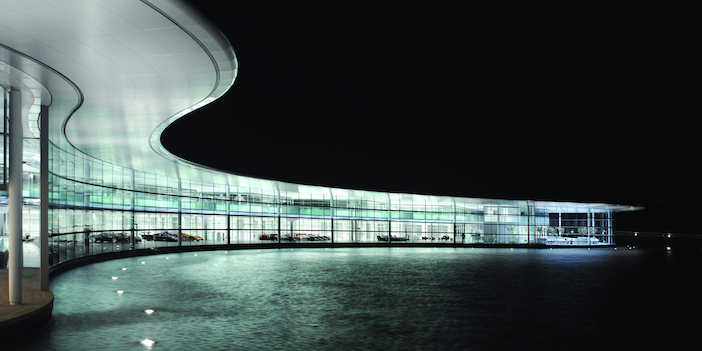

The 12th of May 2024 marked 20 years since the official opening of the McLaren Technology Centre (MTC) in Woking, UK by Queen Elizabeth II. Designed by British architect, Lord Norman Foster, the centre is the headquarters for McLaren Automotive and McLaren Racing, and the McLaren Production Centre added to the site in 2011 produces all of McLaren’s supercars. To celebrate 20 years of the MTC, here are 20 pieces of trivia about the facility.

- The lake which surrounds the building contains over 30 million litres of water. The water is pumped through heat exchangers, which in turn help to cool the buildings and dissipate the heat produced by the wind tunnel.

- During the design process, the dimensions of the building were adapted to ensure no tiles needed to be cut to fit into the building’s design measurements. In the production centre, the test equipment was also designed so that no tiles would need to be cut and they would perfectly fit around the equipment.

- The design of the supporting blades for the building’s facade took inspiration from the suspension wishbones of a Formula 1 car.

- The atmospheric pressure in the McLaren restaurant is slightly lowered and controlled in order to contain the smell of food.

- Over 100,000 trees and shrubs have been planted on the 50-hectare site since McLaren took ownership of the land. There are over 14,000 individual plants in each of the company’s five car parks.

Over 100,000 trees and shrubs have been planted on the 50-hectrae site - The land on which the campus was built was originally home to an ostrich farm and model railway.

- More than 300,000 cubic meters of earth was removed when building the MTC. All of the soil was redistributed around the site and relandscaped.

- If viewed from above, the Technology Centre and lake form a perfect circle.

- The futuristic-looking building has been used as a set for multiple award-winning film and TV productions, including ‘Fast & Furious Presents: Hobbs & Shaw’

- Approximately 43,000 square meters of glass are used in the building.

- It took 2 million hours of labour to build the McLaren Technology Centre.

- The rivers and lakes on the site provide a habitat for 11 species of dragonfly and damselfly, which is unique for such a built-up area.

The rivers and lakes on the MTC site provide a habitat for many species of wildlife – and supercars - The main frame of the building is big enough to house nine Boeing 747 aircraft nose to tail.

- The building is surrounded by a slurry wall 1m-thick and 27m-deep. To dig this out a backhoe excavator, one of only three in the world, had to be brought over from America. It arrived as parts that filled nine articulated lorries and took a week to assemble.

- On a sunny day in July or August, if you walk the boundary path around McLaren Park you can expect to see approximately 350 individual butterflies. More than 25 difference species are seen on McLaren Park every year.

- The design brief for the building was to make it feel 90% NASA, 10% Disney.

If viewed from above, the McLaren Technology Centre and lake form a perfect circle - 100 tonnes of carbon are captured and stored each year by vegetation at the MTC campus.

- The lake is now home to “McLaren bred” carp, which are larger in size than the fish stock that were first introduced.

- The glass lifts on the company’s façade took inspiration from a piston. Built from a one-piece hydraulic ram, they were designed to avoid the need for a telescopic ram which would create unsightly grease along its length.

- Renowned architect Sir Norman Foster of Foster and Partners was responsible for the building’s design. He was also behind the design of Wembley Stadium, the Gherkin in London, Hong Kong airport, and the Century Tower in Tokyo.