Following three years of research, partners in the RE-BREATH brake wear emissions research project say they have nearly completed their work. RE-BREATH (the name stands for ‘reduction of brake wear emissions in the transport sector) is an initiative funded by the European Commission’s LIFE Programme that has involved expert partners in Europe who have been working to improve knowledge of the non-exhausted microparticle emissions generated by braking systems in local public transport (LPT).

This knowledge will then be applied to assess their impact of these emissions on people’s quality of life and the environment, and ultimately for the design and development of an innovative and more environmentally friendly braking system for buses.

Through collaboration between research, business and public institutions, the RE-BREATH partners say they have shown that targeted innovation in braking systems can make a definite contribution to making public transport more sustainable. They also report that real-world road tests conducted over the past 16 months in the cities of Bergamo, Italy and Bratislava, Slovenia confirmed there would be benefits to reducing brake emissions. Bergamo and Bratislava were chosen for the tests as they were identified by the European Environment Agency as being among the urban centres with the highest PM10 concentrations.

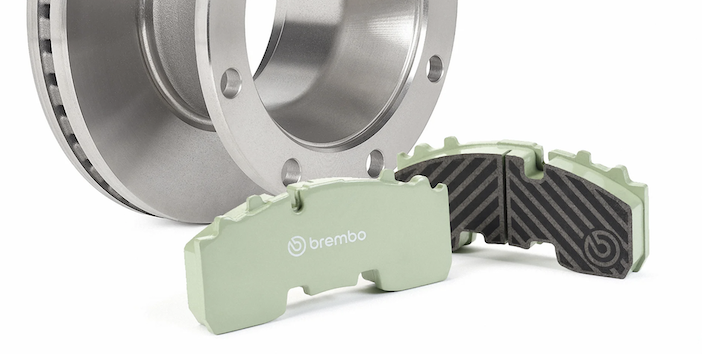

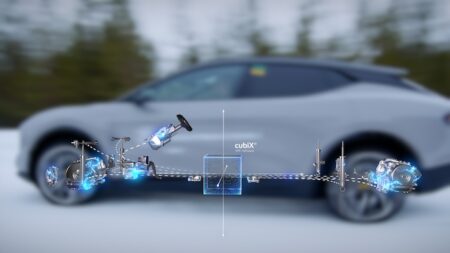

At the heart of the project is an innovative brake system developed by Brembo N.V., with the brake discs made of a special low-wear cast iron, and the brake pads specially designed to work in synergy with these discs. The brake disc has been developed using Brembo’s experience in helping private transport comply with the new Euro7 standard.

The brake pad, scheduled for market launch by the end of 2025, has been specially developed for heavy-duty vehicles and is 100% copper-free. The RE-BREATH partners say the brake system met the goal of maintaining high braking efficiency while significantly reducing particulate emissions compared with conventional systems.

The results of the RE-BREATH project showed a significant increase in the service life of brake discs during road demonstrations compared to historical data: +50% compared to OE (original equipment) systems, and +100% compared to AM (aftermarket) systems.

PM10 emissions were found to have been reduced by 10% compared with the OE system, using the bench test emission factor and the EEA (European Environment Agency) methodology for emissions estimation. A decrease in PM10 concentration between 40% and 70% was shown at bus stops equipped with green barriers, confirming the effectiveness of environmental mitigation interventions.

The project data has been shared with Task Force 5 (PMP group, UNECE) to help develop future emission standards. The tests also revealed their potential scalability in similar, high-demand contexts, and the results paved the way for the wider adoption of sustainable components within bus fleets. Thanks to the collaboration with Arriva Italia and Arriva Slovakia, the system is already being replicated in their light commercial vehicle fleet in Italy (Bergamo and Rome) and Slovenia, anticipating the Euro 7 standard that will come into effect in 2026.

The project also saw the active contribution of the Municipality of Bergamo, which looked into green mitigation interventions at the local level. The National Research Council, the Institute on Atmospheric Pollution (CNR-IIA) and the Institute for the Study of Nanostructured Materials (CNR-ISMN) also worked together to measure air quality and the pollutants emitted by vehicle brakes at bus stops, as well as developing the pollutant dispersion model.

Looking to the future, the project partners believe that continuous collaboration between business, research, public institutions and local communities is essential for promoting further low-impact mobility solutions. The partners also say the replicable model developed through RE-BREATH is now a best practice for building greener, liveable and resilient cities where urban mobility meets the needs of citizens and the environment.