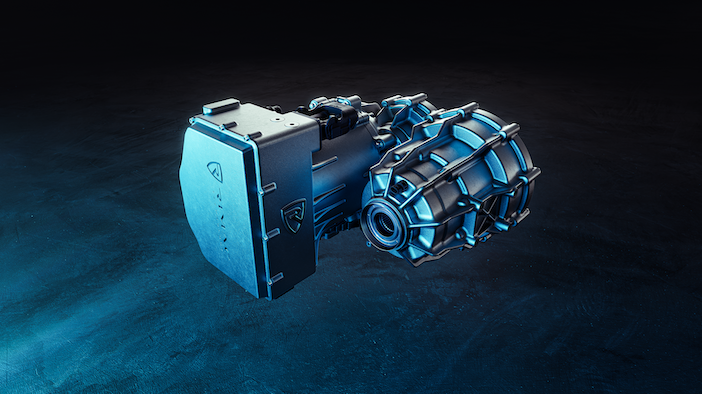

Rimac Technology has developed a new range of next-generation e-axles. Two new models, the SINTEG 300 & 550, are Single EM, ultra-compact, fully integrated e-axles that the company says achieve “all-new levels of performance”, with power density exceeding 8 kW/kg and torque density of over 90 Nm/kg. The e-axles feature a patented ultra-light rotor able to spin up to 25,000rpm, with a novel magnet design delivering high torque and power in a package small enough to fit into carry-on luggage.

Based on Rimac Technology’s Scalable Powertrain Platform, these CoAxial or Offset configurable variants offer between 150 – 360kW and 2,500 – 6,250Nm, making them suitable for performance-focused vehicles across all segments, from hot hatches and sports coupes, to fast sedans and SUVs.

Rimac Technology has also released the High Torque XXL Axle, a production version of its Dual EM EDU 550 e-axle that will enter series production in 2026 for a unspecified global OEM. The company says the current validated system has proven >95% peak efficiency and delivers over 11,000 Nm of axle torque. The mid-volume series programme is backed by a global supply chain, with the highly automatised industrialisation line due to come online at one of Rimac Technology’s production facilities on the outskirts of Zagreb, Croatia.

“These aren’t simply concept technologies; they’ve been developed to be production-ready solutions that will power hundreds of thousands of vehicles in the coming years,” stated Nurdin Pitarević, COO of Rimac Technology.