Nexen Tire, the Korea-based tyre manufacturer, has installed a high-dynamic driving simulator at its central research institute, The Nexen UniverCity, in Magok, Seoul. According to the company this marks the first adoption of such a simulator in the Korean tyre industry, and represents a key turning point in advancing tyre research and development with VR and AI technologies.

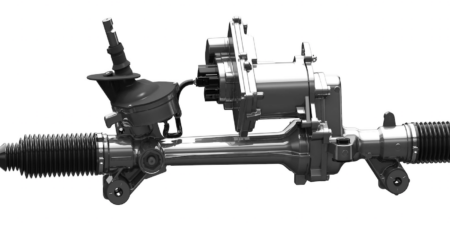

The High Dynamic Driving Simulator simulates real-world conditions in a virtual environment, enabling testing of acceleration, steering response, braking, and other performance metrics in a variety of driving conditions. By using the simulator in its tyre development work, Nexen anticipates it will minimise unnecessary trial-and-error, reduce prototype production and real vehicle testing, and accelerate innovation – all while reducing costs.

Nexen Tire also expects the simulator will enable it to meet original equipment (OE) performance requirements from global automakers more swiftly and accurately. In particular, it is expected to strengthen collaboration in developing tyres for new concept and high-performance vehicles.

As the next step, Nexen Tire plans to gradually establish a full virtual development process that integrates finite element method (FEM) analysis and AI technologies, with the long-term goal of replacing all its tyre tests with simulation-based validation.

“Ahead of the industry trend toward virtual development of vehicles and tyres, the establishment of our High Dynamic Driving Simulator is a strategic investment to lead the future mobility sector,” said John Bosco (Hyeon Suk) Kim, CEO of Nexen Tire. “By combining VR and AI technologies, we will enhance both the efficiency and precision of our R&D while contributing to ESG management.”