Chassis systems supplier BWI Group has developed an automated active roll-control system with a novel method of enhancing ride comfort and driving dynamics.

The system, which is the latest update to the company’s SARC (Semi Active Roll Control) product features a new ‘automatic mode’ that enables a vehicle’s anti-roll bar to disconnect and reconnect seamlessly on demand while driving at speed.

The system update is designed to address an challenge in modern chassis engineering: the increasing mass of vehicles. With SUVs accounting for more than half of new car registrations in Europe in 2024, and BEVs typically weighing around 30% more than equivalent ICE models, engineers are increasingly forced to compromise between roll stiffness for handling and compliance for comfort. Heavier vehicles require stiffer stabiliser bars, which makes it more difficult to achieve ride comfort.

The automatic mode in the SARC system is engineered with the aim of removing this compromise. The anti-roll bar is disconnecting during normal driving, which enables the system to adopt a softer, more compliant baseline, with the stabiliser bar only engaged when required (typically during cornering).

The control unit uses vehicle data, such as steering angle, speed, lateral acceleration and yaw rate, to determine when the bar needs to be reconnected. During high-speed cornering, for example, the bar is reconnected in less than 200 milliseconds in a process that is imperceptible to the driver.

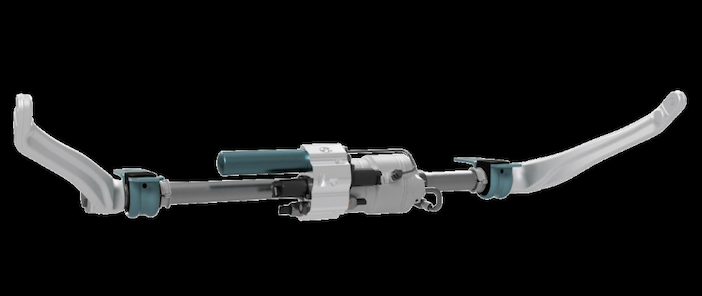

The system is based around a compact rotary actuator that is paired with a fully self-contained hydraulic mechanism. The hydraulic architecture enables the bar to be connected or disconnected even when the wheels are unevenly articulated, which is something mechanical setups typically cannot achieve. Automatic self-centring using the company’s EZ-Latch technology ensures consistent engagement throughout the suspension travel.

“Chassis engineers are continually trying to improve road handling and comfort, but the two goals are often incompatible,” explained Bruno Perree, engineering manager at BWI Group.

“The latest update to SARC removes that compromise, allowing engineers to optimise the roll bar purely for handling as it will be disconnected for the majority of the time. This not only improves comfort but also adds significant off-road capability, which can be a key competitive differentiator in a crowded SUV market.”

SARC is in production on several global platforms, most recently the GWM Tank series, where it is used to balance on-road composure with off-road traction. The addition of SARC’s automatic mode is expected to broaden its application to a wider range of SUVs and BEVs, where managing mass and maintaining ride quality have become engineering priorities.