The behaviour of a tyre on soft soil is a complex interaction. Soft soil can include a variety of materials, such as mud, sand, and other loose or unstable surfaces, which can greatly affect the way a tyre interacts with the ground. These kinds of interactions are difficult to accurately understand through physical tests, as the simple act of driving over the surface of the ground changes its properties.

Consequently, tyre models are crucial in the development of vehicles used in off-road applications. These models should capture critical performance characteristics that are difficult or impossible to record consistently in real-world testing. Repeatability is the best friend of the testing and development engineer.

By using a tyre model specifically designed for soft soil, engineers can better understand the forces and stresses that are placed on the tyre, as well as the resulting performance and behaviour of the vehicle. This information is crucial for designing and optimising tyre, vehicle, and control systems for use in off-road or challenging terrain environments in fields such as defence, mining and agriculture, as well as other off-road applications.

To help engineers with these off-road applications, Mechanical Simulation Corporation added a terramechanics-based tyre model to its CarSim and TruckSim vehicle dynamics simulation software.

The terramechanics-based tyre model simulates the tyre-ground interaction using principles from the field of terramechanics. This type of tyre model is sometimes referred to as a Bekker-Wong model, referring to two prominent researchers who systematically studied the interaction between land vehicles and their terrain.

While the behaviour of a tyre on soft soil is difficult to predict for all cases, terramechanics-based models provide a useful balance between simulation setup time, execution time, and overall accuracy. As such, these models can be used to test different tyre, vehicle and controller configurations in a virtual environment, allowing for faster and more cost-effective development and testing processes.

The VehicleSim terramechanics model works with existing CarSim and TruckSim vehicles and roads, meaning existing simulations can easily be updated to make use of the soft-soil tyre calculations. Input data are in the form of the tyre’s size, soil-specific properties, and coefficients which model the interaction between the tyre and the soil. Example data can be gathered from the terramechanics literature; these sources often include detailed descriptions of how this data may be measured and processed into the required format. Detailed effects include lug height, bulldozing, and multi-pass.

The lug-height effect models the increased traction due to tyre lugs (tread blocks), which protrude from the basic cylindrical shape. This effect is especially relevant for planetary rovers, which use small, rigid wheels with relatively large lugs that protrude. The bulldozing effect predicts how the left or right sidewall experiences resistance when the tyre slides sideways, contributing to the lateral force characteristic.

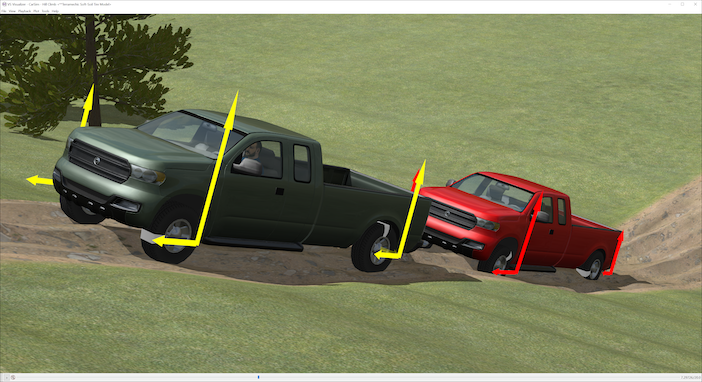

The multi-pass effect gives a sense of how a tyre rolling behind another feels soil properties, namely density. This change in properties implies a change in how much tractive force each tyre can generate, for example.

While the detailed tyre-soil interaction calculations take longer than a typical tyre model, performance is comparable to other high-fidelity tyre models when they are used with CarSim or TruckSim. This means that the overall time from initial setup to simulation results is quick compared to models based on alternative soft-soil formulations.

According to David Kline, Ph.D., lead developer of the terramechanics model, “From the very beginning, we wanted to build a soft-soil capability that functioned with the same ease of use and quick turnaround time that CarSim and TruckSim are known for. With this new model, we hope to extend the value of these terramechanics-based predictions to the vehicle dynamics community at large, rather than building a tool useful only to subject matter experts.”

In addition to the VehicleSim terramechanics-based tyre model, both CarSim and TruckSim include example datasets with typical input data values and off-road manoeuvres, as well as documentation describing how to create or modify terramechanics datasets from within the graphical user interface. CarSim focuses on vehicles with two axles and up to a single trailer, while TruckSim offers the capability for multiple axles and multiple trailers.

CarSim and TruckSim use technology first introduced in 1990 and developed continuously since then, providing efficient, parametric math models. This proven technology, paired with the new terramechanics capability, makes for a compelling and complete vehicle dynamics solution for off-road applications.